Mini Digital Torque Wrenches / Screwdrivers|★Bluetooth

WM-Q(-BT) series (0.9~25 Nm)

★ Connect via Type-C to save data on the computer.

★ Free download of the app (iOS、Android ), and computer software.

★ Lock the wrench via the app, preventing accidental pressing by users..

★ The app allows selecting auto-shutdown time (1 min, 2 min, 5 min, 10 min).

1. Use the piezoelectric effect converted into accurately torque value.

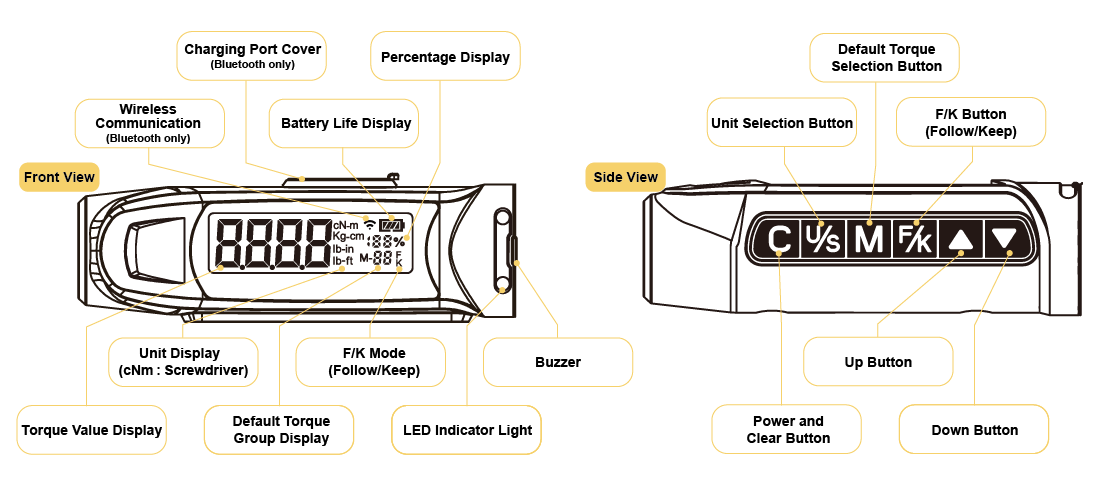

2. Two modes : F(Track) / K(Peak).

3. Warning function : Beep, LED indicator, Vibration function.

4. Four torque units are available : N-m, kgf-cm, in-lb, ft-lb

5. Can store 30 memory setting values.

6. Recording usage frequency and the historical maximum torque.

※※ Suggested accessories: Socket and Bit Socket. ※※

➤Content : Provide storage steel box x1, Certificate of calibration report (Using ISO specification) x1, Operator’s menu(Bilingual) x1, USB insert(Type C)

Note 1: The torque range for precision is between 20% and 100% of the maximum operating value.

Note 2: The factory precision (clockwise) indicates that the clockwise calibration at the factory will adhere to the factory precision standards, while the preset precision serves as a general standard.

※1 Nm=10.2 kgf-cm=0.738 lbf-ft=8.851 lbf-in

-01.png)

Bluetooth New Experience

A brand new Bluetooth Digital Torque Wrench that allows you to monitor torque in real-time through a connection to your smartphone. The wrench automatically records each operation, and the data can be exported as a PDF via the app. It can also be connected to a computer via a cable to save the data in EXCEL or PDF format on the computer using software.

★ APP download (Please open on your mobile phone)

★ Computer software download (Please open on your computer)

★ Manual download (Computer Software + APP)

-EN.png)

-EN.png)

Rechargeable Type Features

Digital Torque Wrench - Cordless" utilizes the latest USB-C charging method that complies with EU standards.

It retains 80% of its capacity even after 300 recharges and has a battery life of up to 3 years (replaceable and serviceable).

With frequent use, it saves approximately 100 zinc carbon batteries a year, making it suitable for users who tighten screws frequently."

IC Protection with Dual Safeguards

To ensure the charging and discharging process is stable and safely protects the user, the circuit board and special battery protection for the charging battery employ a series of protective mechanisms:

⚡ Over-discharge protection - It cuts off power in case of excessively low battery levels to prevent a reduction in battery lifespan.

⚡ Overcharge protection - When the battery reaches full charge, the circuit is disconnected to prevent overcharging.

⚡ Overcurrent protection - The circuit is interrupted in cases of excessive charging or discharging.

⚡ Over-temperature protection - Charging is halted if the temperature exceeds 55 degrees Celsius during the process.

Furthermore, it includes a voltage stabilization mechanism, reverse current protection, and dual-circuit protection ICs, providing you with added peace of mind during use.

(The charging battery is a special specification model with battery protection functions. Please do not replace it with a standard rechargeable battery.)

EN.png)

| Dry Cell Technical Data | Rechargeable Battery Technical Data (Battery : Standard 16650/Mini 10440) | |||||

|---|---|---|---|---|---|---|

| Battery life(continuous operation) |

110 hrs (WS series: 37 hrs) |

Battery life(fully charged used time) |

8-10hrs | Nominal Voltage | 3.7V | |

| Battery life (Standard Mode) |

1 year | Recharge Time | Standard 90-120 mins /Mini 60-90 mins | Nominal Capacity | Standard 1600mAh / Mini 320mAh X2 | |

| Operating temperature |

-10℃~ 60℃ | Storage conditions (Temperature) |

Recharge :10℃ ~ 45℃ Discharge :-10℃~60℃ Storage :-20℃~25℃ (<1 year) -20℃~40℃(<3 months) -20℃~50℃(<1 month) |

Internal Resistance | <60mΩ | |

| Storage temperature | -20℃~70℃ | Lifetime Testing | Capacity remains above 80% after 300 standard charge-discharge cycles. | |||

| Humidity | Up to 90% (not condensed) | Storage conditions (Humidity) |

Work : 20% ~ 85%RH (not condensed) Storage : 40% ~ 85%RH (not condensed) |

Built-in Dual Protection IC Circuit |

Provides protection against over-voltage charging, over-voltage discharging, over-current charging, overheating, overload, and short circuits. | |

| Charging method | USB insert(Type C) | Charging Input Voltage | 5V⎓1A | |||

| Common Specification | |

|---|---|

| No. of memory parameters | 30 |

| LED | 2(1Green + 1Red) |

| Vibration Warning | YES (Activate when set value reaches 90%) |

| Operating modes | Peak hold (K)/Track (F)/Angle (A) |

| Torque Units | Nm, kg-cm, Ib-ft, Ib-in (WM-SD series: cNm, kg-cm, Ib-in) |

| Drop test | 1m |

| Shaking test | 10G(10Hz→55Hz→10Hz/0.8mm) |

| Durability | Over 10000 cycles |

| Environmental test | PASS |

| EMC test | PASS |

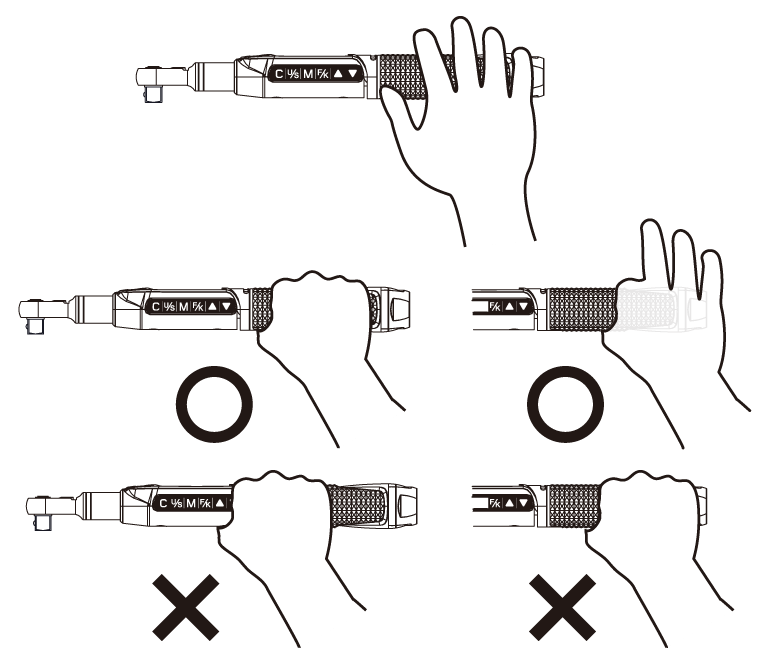

The illustration of using wrench handle.

(For low torque, it is recommended to apply force with a single finger at the center of the handle to reduce errors caused by hand positioning.)